What it is

THERMAL SPRAYING:

What it Was and What it Has Become

by Frank J. Hermanek

On the eve of celebrating the one hundredth anniversary of its discovery, thermal spraying looks back to its roots: early experiments in which liquids were broken up into fine particles by a stream of high-pressure gas…efforts more directed at producing powders rather than constructing coatings. It fell to one Dr. Max Ulrick Schoop of Zurich, who recognized the possibility that a stream of molten particles impinging upon themselves could create a coating. His work and that of his collaborators resulted in the establishment of the thermal spray process. This process has fostered a worldwide industry serving more than 30 technology sectors and generating sales of over $2 billion per year. This article traces the history and development of the principal flame and electrical thermal spray processes.

DEFINITION

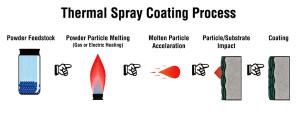

thermal spraying (noun): a group of coating processes in which finely divided metallic or nonmetallic materials are deposited in a molten or semimolten condition to form a coating. The coating material may be in the form of powder, ceramic-rod, wire, or molten materials. (Frank J. Hermanek, Thermal Spray Terminology and Company Origins, 2001, ASM International, Materials Park, Ohio).

In the early 1900’s, Dr. M. U. Schoop and his associates developed equipment and techniques for producing coatings using molten and powder metals. Several years later, about 1912, their efforts produced the first instrument for the spraying of solid metal in wire form. This simple device was based on the principle that if a wire rod were fed into an intense, concentrated flame, (the burning of a fuel gas with oxygen), it would melt and, if the flame were surrounded by a stream of compressed gas, the molten metal would become atomized and readily propelled onto a surface to create a coating. This process was initially referred to as metallizing. Currently the technique is known as oxy-fuel or flame spraying. Oxy-fuel methods include wire, powder (metallic and ceramic), molten metal, ceramic-rod, detonation and high velocity oxy-fuel (HVOF).

In addition to using chemical means to plasticize the input consumables, electrical currents are also used. Typically, electrical energy is used to create a heat source into which powder, and more recently wires, are fed, melted/plasticized, and conveyed onto the surface to be coated. Major commercially employed electrical methods used to construct coatings include non-transferred arc plasma, RF plasma, and wire arc.